Product Information

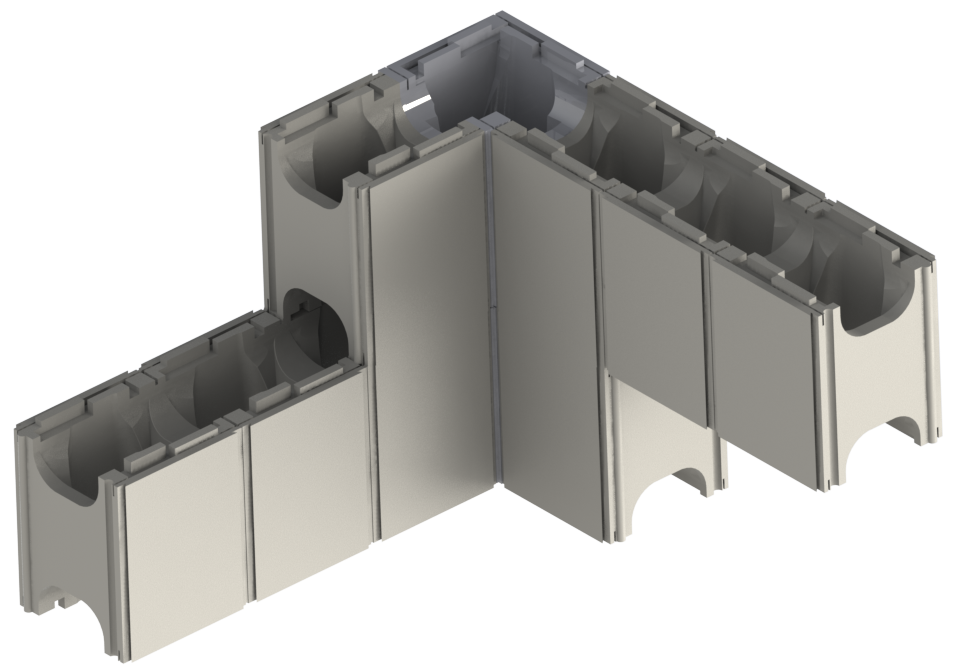

ReddiForm is a screen-grid insulated concrete form product for DIY and experienced home builders.

Advantages

for Developers

& Contractors

Significant labor savings.

Forms have no top or bottom, waste reduced to as low as 2%.

Elimination of expensive reusable formwork.

All-weather construction capability.

Lightweight for ease of loading and unloading.

Eliminates the need for heavy equipment.

Forms aid in building plumb walls and right angles.

Minimized bracing requirements.

Openings os any shape can be placed at any location.

Trusses and joists are attached using traditional methods.

Wiring and plumbing are run with ease.

Forms accept any finish to provide superior aesthetics.

Manufacturing locations through out the U.S.

Snaps together for ease of assembly.

Advantages for End-Users

Highly insulated for savings on heating and cooling bills.

Complete wall insulation -no cold spots.

Inherent strength and durability for long-term value.

Low sound transmission for quieter interior spaces.

Reduced construction cost provide for reduced mortgages.

Environmentally friendly-no CFCs or toxic fumes ever

Made from 100% recyclable expanded polystyrene.

Superior

Stronger Concrete and Additional Economical Living Space

The concrete within the ReddiForm walls is moist cured to optimum hydration rates, providing compression strengths as much as 50% above the standard rated capacity. This gives anyone using the ReddiForm system an added factor of safety and confidence in the integrity and quality of the walls. If used to construct basements, the stay-in-place insulating forms provide ready-to-finish interiors that are clean, dry and comfortable. This creates added living space at a fraction of what it cost to finish a conventional block or concrete basement. This additional living space can easily be converted into an office, family room, workshop, storage area or play space. It can generate a higher selling price for any size home by virtue of its larger area and added versatility.

Versatile

ReddiForm is the

Ultimate Base for Any Finishing Material

The dense expanded polystyrene insulation provides an excellent base for adhered finishes. The optional plastic fastening strip is an excellent attachment medium for mechanical fasteners of all sorts. This combination creates a versatile substrate for products such as:

- Stone and Stone Veneer.

- Brick and Cementitious Stucco.

- Synthetic and Cementitious Stucco.

- Wood, Aluminum and Vinyl Siding.

- All Types of FRP and Plastic Sheeting.

- Brick and Cementitious Stucco.

- Synthetic and Cementitious Stucco.

- Wood, Aluminum and Vinyl Siding.

- All Types of FRP and Plastic Sheeting.

Green

Environmentally Friendly and Highly Insulated

Expanded polystyrene (EPS) insulation is the most economical and safe insulation in the construction industry today. It is stable, water resistant and inexpensive. Reddi-Form uses EPS to provide a tested R-value of 20, under the ASTM C-236 method. Studies by the Florida Solar Energy Center found that houses insulated with EPS had energy savings of 13 percent over houses insulated with fiberglass and cellulose. One of the most basic advantages of using EPS insulation is its ability to hold a consistent R-value for the life of the product, unlike isocyanate and urea-based foams. This amazing energy efficiency provides added benefits such as: reduced rates on mortgage services, reduced energy cost through power company programs and instant acceptance into energy conservation legislation such as the Oregon DOE building code amendments. Reddi-Form is the only stand-alone system which meets Oregon's code, the most stringent energy code in the nation.

Efficient

Save in Costs and Build Faster

CF walls provide a tight, low air filtration wrap to your home. This is the first step in controlling the indoor air environment.

- ICF walls reduce air infiltration by 75%.

- Eliminate dust mites.

- Prevent dangerous and costly mold.

The effects of hay fever, asthma, and other airborne allergies can be greatly alleviated as a direct result of the reduced leakage of outside air, which brings dust, pollen, and other pollutants.

Indoor air pollution is a great health concern today. ICF walls are non-toxic. The measurement of air contents of actual ICF houses shows an almost complete absence of any emissions.

- ICF walls reduce air infiltration by 75%.

- Eliminate dust mites.

- Prevent dangerous and costly mold.

The effects of hay fever, asthma, and other airborne allergies can be greatly alleviated as a direct result of the reduced leakage of outside air, which brings dust, pollen, and other pollutants.

Indoor air pollution is a great health concern today. ICF walls are non-toxic. The measurement of air contents of actual ICF houses shows an almost complete absence of any emissions.

Homes made with ICF are sometimes called “1,000-year homes” because there’s little to prevent them from surviving intact for hundreds of years. The walls are strong enough to withstand up to 250 mph hurricane winds and tornadoes, earthquakes, and are fire-resistant for up to 4 hours. They’re unlikely to suffer from slow degradation the same way wood-frame walls do, so they stand the test of time.